Screw displacement piles (SDP) and Vibro displacement piles (VDP) are a fast and effective technology for deep, pile foundations for various structures.

Common uses

Process

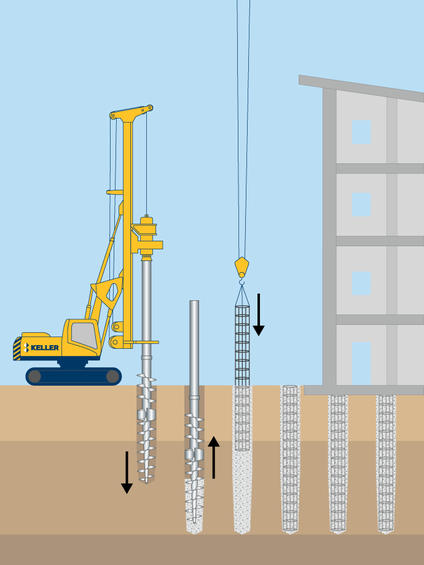

Keller Polska offers two types of displacement piles. Screw displacement piles (SDP) made with a displacement head or a drilled pipe terminated with a lost base, and Vibro displacement piles (VDP) made by vibrating steel pipes into the ground using vibratory hammers.

The drill makes piles by displacing the soil from side to side as it’s screwing (SDP), or by pushing soil through a pipe vibrated into the ground (VDP). Concrete is then fed into the resulting hole from below under pressure.

Reinforcement can be introduced before or after concreting, depending on the technique used. After concreting, it is usually done using vibration.

During design, Keller can use its own software and finite element methods (FEM), Plaxis software or classical analytical methods.

Advantages

Quality assurance

Performance parameters are recorded digitally during execution. Test plots are made to verify the assumed production parameters, static test loads (including with separation of shaft and base), dynamic test loads, pile integrity tests and tests of concrete compressive strength.